Discussion

Based on the literature review this section discusses the pros and cons associated with specifying low rolling resistance, including safety issues and the level or scale of reductions in CO2 that may be achievable.

Advantages

The literature review clearly shows that rolling resistance has an effect on fuel consumption and hence exhaust emissions, particularly CO2. Any increase in rolling resistance will result in a higher fuel consumption with a corresponding increase in GHG emissions. Road transport is one of the few energy consuming sectors where the emissions are increasing. The MIRIAM project5 highlighted that passenger cars in Europe accounted for approximately 12% of all CO2 emissions. It is therefore desirable to specify road pavements with low rolling resistance. However, the challenge is to determine how this can best be accomplished in a cost-beneficial way.

The literature review highlighted that significant future reductions in fuel consumption and GHG emissions are likely to come from more efficient propulsion systems. Examples include advanced technologies such as plug-in hybrids, electric vehicles and the possible use of hydrogen fuel cells. An important caveat is that the production of electricity needs to come from renewable sources.

It is clear that no single development will resolve the growing problem of vehicle fuel consumption and GHG emissions and it is clear that a collective effort from all corners of society is required to identify carbon saving opportunities. Savings in rolling resistance are likely to be comparatively small compared to the energy lost to engine and driveline inefficiencies. Nonetheless, it still represents an important opportunity to reduce fuel consumption, particularly as rolling resistance is seen to increase with the use of heavier electric vehicles.

Much research has been carried out by the tyre industry and this has been driven by the premise that rolling resistance accounts for about 25% to 30% of a vehicle’s fuel consumption, dependent on the vehicle type. Popular marketing for low rolling resistance tyres claim they can reduce rolling resistance by 10%, which will result in a 2 to 3% saving in fuel consumption. However, the test for rolling resistance does not accurately mimic the in situ tyre-road interface conditions.

The review covered European research conducted over the last 40 years and the most recent work tends to suggest that rolling resistance measurement and modelling are still in their infancy. It is acknowledged that International standards exist for testing tyres, but they do not consider the tyre‑road interaction and do not appear to present a holistic approach. Testing road surfaces to evaluate the tyre-road interaction appears to be extremely challenging owing the properties of the touching surfaces that are constantly changing. As stated earlier, the US Department of Energy describes rolling resistance as a complex phenomenon and nearly all operating conditions can affect the final outcome.

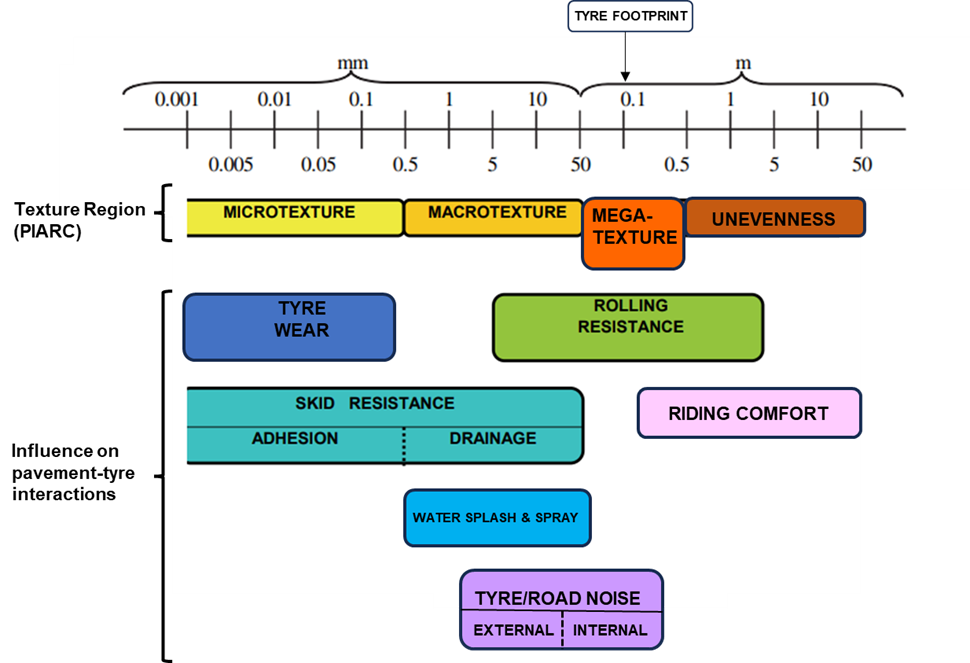

The main approach to quantifying rolling resistance that is related to pavement type and condition is to develop a model that can forecast the reduction of CO2 emitted by vehicles. These models utilise existing data on the surface profile which contains a range of texture wavelengths. Figure 3-1 summarises work developed by PIARC and others on how certain texture wavelengths will affect features such as rolling resistance, skid resistance, noise, riding comfort, tyre wear, water splash and spray. The figure illustrates the complexity of optimising the surface profile for a road across the texture wavelength range. For example, it can be seen that reducing texture amplitudes for rolling resistance will also be beneficial for noise generation but could potentially be detrimental to certain aspects of skid resistance, such as drainage and spray reduction. Similarly, it can be seen that a reduction in microtexture would be beneficial for tyre wear and particulate emissions but from a road safety perspective microtexture is required for both low and high-speed skid resistance.

Models have been developed to forecast the amount of CO2 emitted by vehicle rolling resistance in relation to pavement type and condition. However, studies have shown that they can produce different results and are sensitive to the level of the pavement condition and its deterioration rate.

Road trials and rolling resistance measurements indicate that low rolling resistance tyres have a significant influence on reducing rolling resistance, which is then followed by road roughness, particularly in the megatexture range (50-500mm). Trials in Denmark have configured mixtures that possess a thicker coating of mortar with low macrotexture (average MPD = 0.5mm). However, construction quality was also closely monitored with a view to producing a smooth or even surface with low roughness or IRI values.

In general, low rolling resistance pavements are likely to reduce tyre wear and particulate emissions. However, the review suggests that other measures will be more effective, such as technology that attracts tyre wear particles, and legislative controls to ensure low rolling resistance tyres do not comprise toxic components.

Disadvantages

The literature review suggests that the advantages of rolling resistance far outweigh the disadvantages. As well as reducing fuel consumption and GHG emissions, it is likely that low rolling resistance pavements will be smoother, which bring additional benefits, such as: improved longevity or durability; less wear and tear on vehicles; reduced maintenance costs; and provide a more comfortable ride for road users.

Nonetheless, a fine balance needs to be struck to ensure that pavements are safe for all road users, particularly under wet conditions. It is essential that pavement surfaces provide adequate friction so that drivers can brake and manoeuvre safely when the conditions demand it. In optimizing texture amplitudes for rolling resistance (see Figure 3-1), care needs to be taken that textures important to skid resistance are not compromised, such as drainage for high-speed skidding resistance, and minimizing splash and spray.